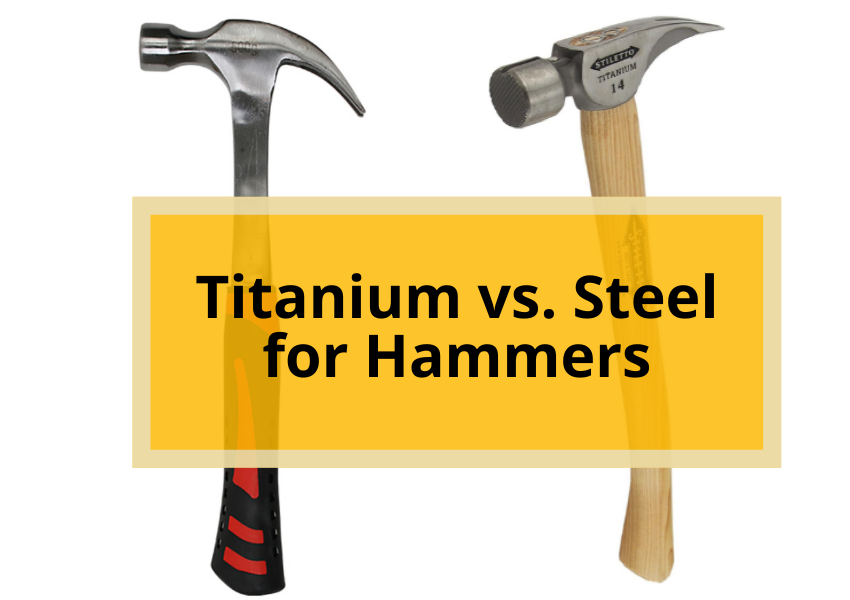

Hammers are one of the most commonly used hand tools. They are used for driving nails, fitting parts, forging metal, and breaking up objects. Hammers come in a variety of styles and are made from different materials depending on their intended use.

Two of the most popular materials for hammer heads are steel and titanium. Both offer advantages and disadvantages compared to the other. This article will examine the differences between titanium and steel hammers to help you determine which is best for your needs.

Steel Hammers

Steel is one of the most common traditional materials used to make hammer heads. Steel hammers have been around for centuries.

Key advantages of steel hammers

Affordability

Steel hammers are relatively inexpensive compared to other materials. They offer good value for money.

Durability

Steel is strong and withstands the frequent high-impact blows that hammers experience without damage. Steel hammers have a long service life.

Shock absorption

Steel has some shock absorbing properties which reduces vibration and impact when driving nails or shaping metal. This helps protect the user’s joints.

Versatility

Steel hammers can be used for a wide range of applications from driving large nails to delicate metal work. Steel also maintains its strength across a wide temperature range.

Stronger than titanium

Steel is a stronger metal than titanium, so steel hammers are better suited for heavy-duty applications.

More widely available

Steel hammers are more widely available than titanium hammers, so you can find them at most hardware stores.

Ease of re-facing

Steel hammer faces become indented and mushroom with use. They can easily be re-faced by grinding the surface to renew the optimal flat face.

Key disadvantages of steel hammers

Heavy

Steel hammers are heavier than titanium hammers, which can make them more difficult to use for extended periods of time.

More vibration

Steel hammers do not absorb vibration as well as titanium hammers, which can increase the risk of injuries such as carpal tunnel syndrome.

Susceptible to rust

Steel is susceptible to rust and corrosion, so steel hammers should not be used in wet or humid conditions.

Also read : ESTWING Ultra Series Hammers Black and Leather

Titanium Hammers

Titanium hammers entered the market in the 1980s as a high-tech alternative to steel.

Key Aadvantages of Titanium Hammers

Lightweight

Titanium has a lower density than steel, making titanium hammers around 25% lighter than comparable steel hammers. The lighter weight reduces fatigue when working for extended periods.

Strength

Titanium has an excellent strength-to-weight ratio. Titanium hammers are just as strong as steel hammers despite their lighter weight.

Rust resistant

Titanium is highly resistant to corrosion and rust damage. This allows titanium hammers to better withstand wet and humid environments.

Vibration dampening

Titanium more effectively dampens vibration and impact shocks compared to steel. This helps prevent joint injuries and makes driving nails easier.

Longer lasting faces

The titanium facial material is highly durable and maintains its flat face longer before requiring re-facing.

Ergonomic

The lighter titanium head combined with an ergonomic friction grip handle reduces strain on the user’s hands, wrists, and elbows.

Key Disadvantages of Titanium Hammers

Expensive

Titanium hammers are more expensive than steel hammers.

Not as strong as steel

Titanium is not as strong as steel, so titanium hammers may not be suitable for the most demanding applications.

Less Versatility

Tiitanium hammers are also not recommended for metalworking applications as sparks can fuse to the facial material.

Also read : Should You Get a Titanium Hammer?

Head to Head Comparison

Here is a direct comparison of the key factors when choosing between titanium and steel hammers:

– Cost – Steel hammers are significantly cheaper. Titanium hammers cost 2-4 times more.

– Weight – Titanium hammers are around 25% lighter on average.

– Strength – Both materials have excellent strength for hammer heads.

– Rust/Corrosion – Titanium wins hands down.

– Vibration dampening – Titanium dampens vibration and shock better.

– Facial durability – Titanium facial material lasts significantly longer.

– Versatility – Steel hammers can be used for more applications.

– Ergonomics – Titanium offers better balance and an ergonomic grip.

– Re-facing – Steel is easier to re-face than titanium.

Which is Best for You?

Choosing between a titanium or steel hammer depends on your specific needs and preferences. Here are some recommendations for selecting the best material:

– If you drive a lot of nails or do repetitive hammering, choose titanium for the vibration reduction and lower fatigue.

– For metal forming or shaping, steel is the better choice due to its versatility and ability to be re-faced.

– If you work outdoors in wet conditions, titanium will resist corrosion better.

– For occasional DIY use, a steel hammer is likely the more economical choice.

– Professionals who hammer all day should consider investing in a quality titanium hammer for the ergonomic benefits.

– If your budget is tight, steel hammers offer the most bang for your buck.

Here are some additional tips for choosing the right hammer:

- Consider the size and weight of the hammer. Choose a hammer that is comfortable for you to hold and swing.

- Look for a hammer with a good grip. The grip should be comfortable and slip-resistant.

- Inspect the hammer head for any defects. The hammer head should be smooth and free of cracks or imperfections.

- Read reviews of different hammers before you buy one. This can help you to choose a hammer that is well-made and durable.

Also read : Stiletto Martinez Tools M1-15-Ounce Titanium Framing Hammer

Conclusion the Right Hammer Matters

Whichever material you choose, select a hammer that feels balanced and comfortable in your hand. Proper technique is also critical – let the hammer do the work, don’t swing it wildly.

With the right hammer and technique, driving nails and other hammering tasks will be easier, safer and more productive. Investing in a quality hammer made from durable materials that suits your needs will be worthwhile. Understanding the comparative benefits of titanium vs steel will help you make an informed choice for your next hammer purchase.

FAQ

Which type of hammer, titanium or steel, is more durable?

Steel hammers are generally more durable overall. The steel head can withstand repeated heavy impacts without damage. However, titanium has greater facial durability, meaning the striking surface lasts longer before requiring re-facing.

Is a titanium hammer good for driving large nails?

Yes, titanium hammers have plenty of strength to drive large nails. Though titanium is lighter than steel, it maintains excellent strength for hammering tasks.

Can a titanium hammer be used for auto body work?

Titanium is not recommended for auto body applications because it can spark when striking metal. This could fuse titanium particles to the metal. A steel hammer is better for metal shaping and auto body work.

Is a titanium hammer good for framing or construction?

A titanium framing hammer is an excellent choice for the repetitive hammering involved in framing walls. The lighter weight and vibration dampening of titanium reduces fatigue over long workdays.

Is it hard to re-face or sharpen a titanium hammer?

Yes, titanium is more difficult to re-face than steel. Titanium requires diamond abrasives to grind and reshape the facial material.